Your solution for transit components

Cooling Fan Repair, Rebuild, and Balancing

We specialize in rebuilding and balancing various cooling fans. Fans are balanced to a maximum vibration amplitude of less than .002".

Electronic Circuit Board Repair and Manufacture

Industry depends on many different types of circuit boards, control modules, contacts, relays and voltage regulators, and logic centers. We remanufacture a wide range of electronic components for the transportation industry, and automated machine tool control industry. We repair and test a wide range of these items from a variety of manufactures. We have provided new versions of many obsolete control and circuit boards.

Electric Motor Repair and Production

Replacement electric motors for some vehicles are becoming increasingly difficult to source. We repair many types of electric motors through our special rewinding services. For many applications we provide or manufacture new motors. We are also a source for replacement brushes, brush holders, fuses, slip rings, friction material, and contacts.

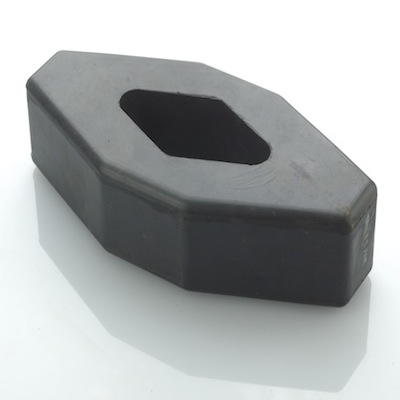

Rubber Molding and Bonding

We provide custom molds for a variety of items including rod bushings, suspension products, bonded rubber wear plates and machinery mounts. We also provide a source for high and low pressure static and sliding seals.

Sheet Metal Forming, Welding and Fabrication

Often component drawings are not available. Piece parts and assemblies can generally be duplicated by sample. Investigation into the application and metallurgical analysis starts the process. We have provided car body panels, doors, hatches, seat panels, sliding windows, and a wide variety of other items.

Water Jet Machining

This process is used for profiling components with complex shapes and difficult materials. We have provided both close tolerance glass profiles and rough cutting blanks for metal turnings. This method can be used for metal, glass, ceramic, plastic, and many other materials that require a computer controlled, extremely detailed cutting process.

CNC Machining Services

Components with complex curvatures or that require multiple step process and extremely close tolerances are CNC machined. This process produces very close repeatable tolerances.

Wood Working and Fabrication

Metal is NOT all we do. We provide a variety finished wood products. These include floor panels and other laminate and wood combination parts, as well as metal covered wood components.

Fiberglass Fabrication

We make a variety of custom fiberglass panels and parts for cars and busses by sample and by dimensional specifications. We have enclosures that are capable of curing structural parts at their neutral adjusted temperature (the average temperature the parts will endure in service).

Plastic Injection, Casting and Fabrication

Cold molding, heated injection molding, and machining are offered in providing custom and replacement plastic parts. We have provided light lenses, inspection ports, impact covers, wear pads and noise reduction pads. Items machined for detail include push button shields, dash bulb holders, nylon cams and spacers.